Floor deck roll forming machine,Floor deck plate roll forming machine,Floor decking roll forming line

Basic Info

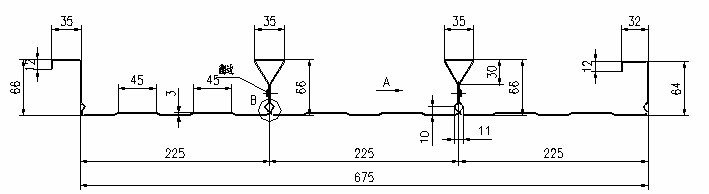

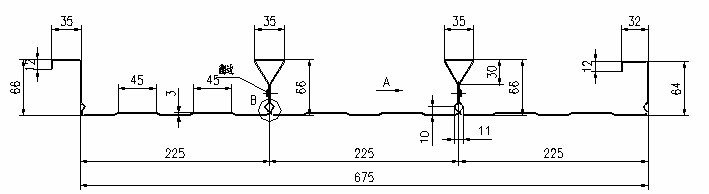

Model No.: YX65-225-675

Product Description

Specifications 1.Floor Decking Roll Forming Machine

2.Pass CE, european standerd

3.Fully automatically

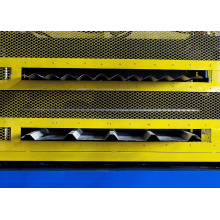

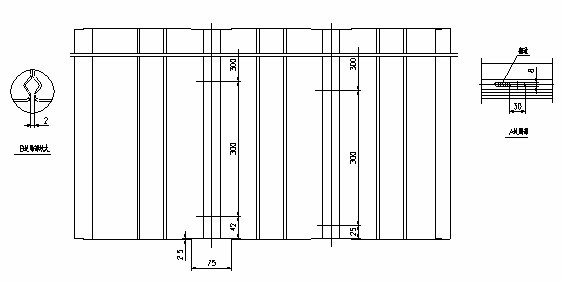

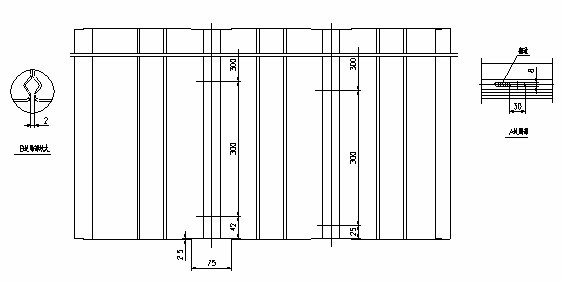

Product name:Floor Decking Roll forming machine A, main technical parameter 1, Unpowered feeding shelf: passive feeding, manual tensing 2, Loading-bearing of feeding shelf: 8T 3, Sheet coil width: 1200mm 4, Forming effective width: 675mm 5, Forming thickness: 0.8-1.2mm 6, Main Forming Machine station: main roller:48 groups 7, Hydraulic oil tank power: 5.5KW 8, Stitching motor power: 5.5KW 9, forming machine motor power:13×3=45KW 10, Forming speed: 8M/min 11, Roller dimension: 90mm 12, Transmission: motor retarding device (transaction by chain) 13,Cutter material: Cr12MOV 14,Roller material: 45# after treatment 15,Roller: Surface coating with chrome, thickness is 0.05mm per side. 16,Frequency: DNAFUSS, America 17, Computer: PCL, Mitsubishi FX—IS series 18, Computer operation board: Xinjie OP320A 19,Out-put type: Roller type 20,Out-put table length: 18000mm B, Components It’s composed of passive feeding shelf, hydraulic front-cut device, punching device, main forming machine, stitching punching device, hydraulic forming cutting device, hydraulic station, computer control cabinet, and out-put table.

Passing CE, Guaranteed quality, PLC control system, Easy and to handle Whole-process technical trace service Direction to production line operation Design according to your requirements. Contact us if you need more details on Cold Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Floorboad Forming Machine、Floor Deck. If these products fail to match your need, please contact us and we would like to provide relevant information.

2.Pass CE, european standerd

3.Fully automatically

Product name:Floor Decking Roll forming machine A, main technical parameter 1, Unpowered feeding shelf: passive feeding, manual tensing 2, Loading-bearing of feeding shelf: 8T 3, Sheet coil width: 1200mm 4, Forming effective width: 675mm 5, Forming thickness: 0.8-1.2mm 6, Main Forming Machine station: main roller:48 groups 7, Hydraulic oil tank power: 5.5KW 8, Stitching motor power: 5.5KW 9, forming machine motor power:13×3=45KW 10, Forming speed: 8M/min 11, Roller dimension: 90mm 12, Transmission: motor retarding device (transaction by chain) 13,Cutter material: Cr12MOV 14,Roller material: 45# after treatment 15,Roller: Surface coating with chrome, thickness is 0.05mm per side. 16,Frequency: DNAFUSS, America 17, Computer: PCL, Mitsubishi FX—IS series 18, Computer operation board: Xinjie OP320A 19,Out-put type: Roller type 20,Out-put table length: 18000mm B, Components It’s composed of passive feeding shelf, hydraulic front-cut device, punching device, main forming machine, stitching punching device, hydraulic forming cutting device, hydraulic station, computer control cabinet, and out-put table.

| Model | |

| Typle | color steel sheet |

| Thickness | 0.8-1.2mm,yield stress:230-300(mpa) |

| forming speed | 17(m/min) |

| roller material | GCR15#steel with chrome |

| roller driven type | chain transmission |

| controller | PLC |

| Operation | Touch screen and button |

| Hydraulic system pressure | 12(mpa) |

| Hydraulic station motor power | 11(kw) |

| Main motor power | 15(KW) |

Product Categories : Floor Deck Machine

Premium Related Products

Other Products

Hot Products

Tile Roof Ridge Cap Roll Forming MachinePassed CE and IOS Ajustable Door Frame Roll Forming Machinery/making machine/Lager-span curve rolling forming machinehidden roof panel forming machineryArc Slab Roof Metal Stud Roll Forming MachineSimple Slitting MachineSelf-locked Roof Panel Roll Forming MachineGlazed Steel Roof Tile Sheeting Making machineFloor deck roll forming machine,Floor deck plate roll forming machine,Floor decking roll forming lineBending Roll Forming Machinecolored steel tile roll forming machinePU corrugated roof sheet forming lineDownspout Steel Corrugated Metal Pipe Making Machine in wuxiOctagonal Steel Rolling Pipe Bending Machine with CE provedSpeedway guard rail roll formingsingle adjusting C purlin forming machine