Dry Type Transformer Epoxy Resin Casting Molds

Basic Info

Model No.: S11

Product Description

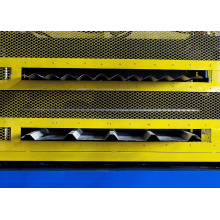

Model NO.: S11 Usage: Power Transport Package: Nude Packing Phase: Three Trademark: Haoshuo Origin: China Dry Type Transformer Epoxy Resin Casting Molds 1.Purpose of the product: Divided into soft and hard molds, casting mold is used for casting of epoxy dry-type transformer coils and is an essential tool for production of dry-type transformer coils. 2.Components of the device The hard mold is composed of outer mold, inner mold, outgoing bar and seal strip.

The soft mold is composed of outer mold, inner mold, seal strip, clamping plate and pressing plate.

3. Main technical parameters of Casting mold of dry-type transformers

4. Functional features

1) It is designed according to the casting requirements of the user and the user only need to provide the coil size.

2) The soft mold is designed properly with convenient use.

3) Stainless steel guarantees the casting quality.

4) Short processing cycle guarantees the delivery time of the user.

5) With obvious reduction in cost compared with former hard mold, soft mold is suitable for small batch production of transformers

FAQ: 1) Q: Are you manufacturer or trading company? A: We are manufacturer and trading company . 2) Q: Do you provide installing and training overseas? A: Overseas machine install and worker training services are optional. 3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians. 4) Q: How does your factory do regarding quality control? A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment. 5) How can I trust you that machines pasted testing running before shipping? A: 1) We record the testing video for your reference. Or, 2) We welcome your visit us and test machine by yourself in our factory. 6) Q: Do you sell only standard machines? A: No. Most machines are made to order. 7) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).

Contact us:

Tel: +86 151 5222 5198

Contact us if you need more details on Casting Mold. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal Casting Mold、Antique Cast Iron Molds. If these products fail to match your need, please contact us and we would like to provide relevant information.

The soft mold is composed of outer mold, inner mold, seal strip, clamping plate and pressing plate.

3. Main technical parameters of Casting mold of dry-type transformers

| Soft mold (hard mold) | Soft mold (hard mold) | Hard mold |

| 100KVA/10KV | 2000KVA/10KV | 12500KVA/35KV |

| 315KVA/10KV | 2500KVA/10KV | 16000KVA/35KV |

| 400KVA/10KV | 2000KVA/35KV | 20000KVA/35KV |

| 500KVA/10KV | 3150KVA/35KV | |

| 630KVA/10KV | 4000KVA/35KV | |

| 800KVA/10KV | 6300KVA/35KV | |

| 1000KVA/10KV | 8000KVA/35KV | |

| 1600KVA/10KV | 10000KVA/35KV | |

| Detailed dimensions shall be designed according to the coil size of the user. | ||

4. Functional features

1) It is designed according to the casting requirements of the user and the user only need to provide the coil size.

2) The soft mold is designed properly with convenient use.

3) Stainless steel guarantees the casting quality.

4) Short processing cycle guarantees the delivery time of the user.

5) With obvious reduction in cost compared with former hard mold, soft mold is suitable for small batch production of transformers

FAQ: 1) Q: Are you manufacturer or trading company? A: We are manufacturer and trading company . 2) Q: Do you provide installing and training overseas? A: Overseas machine install and worker training services are optional. 3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians. 4) Q: How does your factory do regarding quality control? A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment. 5) How can I trust you that machines pasted testing running before shipping? A: 1) We record the testing video for your reference. Or, 2) We welcome your visit us and test machine by yourself in our factory. 6) Q: Do you sell only standard machines? A: No. Most machines are made to order. 7) Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided).

Contact us:

Tel: +86 151 5222 5198

Contact us if you need more details on Casting Mold. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Centrifugal Casting Mold、Antique Cast Iron Molds. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Transformer Machines > Others Transformer Machines

Premium Related Products

Other Products

Hot Products

Tile Roof Ridge Cap Roll Forming MachinePassed CE and IOS Ajustable Door Frame Roll Forming Machinery/making machine/Lager-span curve rolling forming machinehidden roof panel forming machineryArc Slab Roof Metal Stud Roll Forming MachineSimple Slitting MachineSelf-locked Roof Panel Roll Forming MachineGlazed Steel Roof Tile Sheeting Making machineFloor deck roll forming machine,Floor deck plate roll forming machine,Floor decking roll forming lineBending Roll Forming Machinecolored steel tile roll forming machinePU corrugated roof sheet forming lineDownspout Steel Corrugated Metal Pipe Making Machine in wuxiOctagonal Steel Rolling Pipe Bending Machine with CE provedSpeedway guard rail roll formingsingle adjusting C purlin forming machine