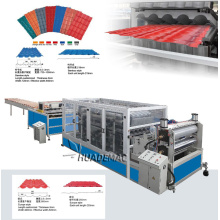

Glazed steel tile forming machine

Basic Info

Model No.: YX24-183.3-1100

Product Description

2, Components of line:

2, Components of line: Name | Model/Name | Quantity | Technical description |

1.Decoiler system | 5 T manual decoiler | 1 set | manual tensing,bearing weight 5 tons |

2.Main Forming system | Guiding device | 1set | 1.Roller 45 steel with treatment, designed by professional software,accuracy 2.Guiding column roller fixer system,better roller position and longer time 3.Entire chain drive system to ensure the roller movement 4.Cutting blade Cr12 with quenching |

Roll forming system | 1 set | ||

Hydraulic cutting device | 1set | ||

3.Runout table | 1.5M support table | Support the final production, roller design to make sure the panel without any scratch | |

4.Hydraulic system | 1 set | Supply the power for cutting system | |

5.Electranic control system(PLC) | 1 set | 1.PLC control,fully automatically, cut to length 2.Button operation,big touch screen 3.AC frenquency to adjust speed | |

Forming size | 5200mm*1400mm*1200mm |

Feeding width | 1000mm |

Equipment weight | 3200kg |

Material of shaft | 45#steel adjustable treatment |

Out diameter of shaft | φ70mm |

Material of roller | Cr12, quenched treatment HRC58-60°C |

Number of forming rollers | 10 rows |

Main frame | 300 H steel |

Thickness of medium plate | 14mm |

Transportation system | Chain transportation |

Thickness of chain | 6 points |

Main motor power | 4 KW |

Pump station power | 3 KW |

Forming speed | 5000-6000mm/min |

Rolling thickness | 0.5-0.6mm |

Product Categories : Glazed Tile Forming Machine

Premium Related Products