Metal steel door frame roll forming machine /door frames made machine

Basic Info

Model No.: YX

Product Description

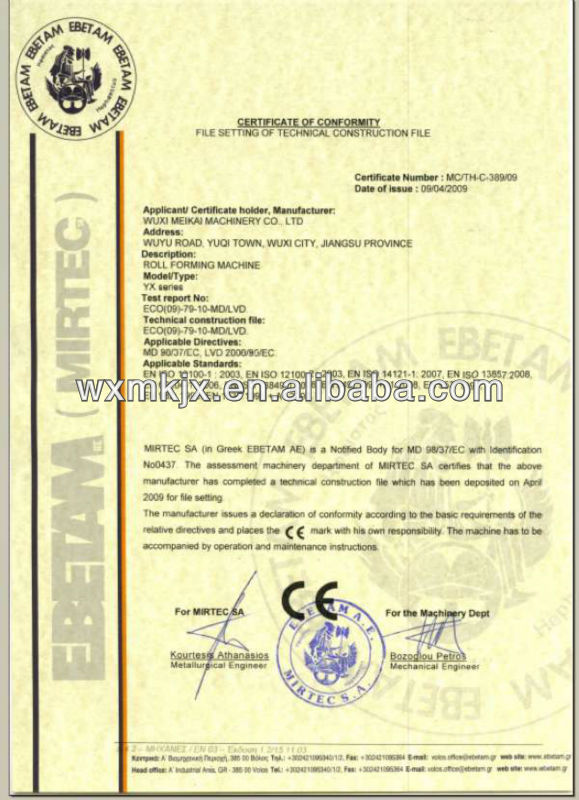

2.Passing CE, Guaranteed quality,

3.PLC control system

4.Whole-process technical trace servic

Roll Forming Machine for Door Frame 1, Profile

2,Components of line:

2,Components of line: Name | Model/Name | Quantity | Technical description |

1.Decoiler system | 5 T manual decoiler | 1 set | manual tensing, bearing weight 5 tons |

2.Main Forming system | Guiding device | 1set | 1.Roller 45 steel with treatment, designed by professional software, accuracy 2.Guiding column roller fixer system, better roller position and longer time 3.Entire chain drive system to ensure the roller movement 4.Cutting blade Cr12 with quenching |

Roll forming system | 1 set | ||

Hydraulic cutting device | 1set | ||

3.Runout table | 1.5M support table | Support the final production, roller design to make sure the panel without any scratch | |

4.Hydraulic system | 1 set | Supply the power for cutting system | |

5.Electranic control system(PLC) | 1 set | 1.PLC control, fully automatically, cut to length 2.Button operation, big touch screen 3.AC frequency to adjust speed | |

Decoiler: umbrella type, passive feeding, manual tensing Bearing weight: 5 Tons (2)Main Forming Machine

Decoiler: umbrella type, passive feeding, manual tensing Bearing weight: 5 Tons (2)Main Forming Machine  Decoiler, passive feeding, manually tense Decoiler bearing: 5T Main motor power: 7.5kw Forming stations: 19 stands Main shaft diameter: ¢65mm Hydraulic station power: 3kw Roller material: Gcr15 bearing steel with quenching, hardness 58°- 62° Yield strength: <300MPa PLC control, cut to length, length tolerance≤2mm Profile measure up to Chinese GBT/12755-91 standard (3)PLC control system

Decoiler, passive feeding, manually tense Decoiler bearing: 5T Main motor power: 7.5kw Forming stations: 19 stands Main shaft diameter: ¢65mm Hydraulic station power: 3kw Roller material: Gcr15 bearing steel with quenching, hardness 58°- 62° Yield strength: <300MPa PLC control, cut to length, length tolerance≤2mm Profile measure up to Chinese GBT/12755-91 standard (3)PLC control system  Computer adopt PLC control system, Mitsubishi FX-IS series Computer operating board: Xinjie OP320A Frequency: American Danfoss Function and operation:Control the starting, operation and stopping of the complete line, including distribution section, operation table, counting instrument. Use PLC to control ,set and adjust the length. Both man-made and auto operations: on the man-made condition, each equipment can be operated by switch; (4)Hydraulic system

Computer adopt PLC control system, Mitsubishi FX-IS series Computer operating board: Xinjie OP320A Frequency: American Danfoss Function and operation:Control the starting, operation and stopping of the complete line, including distribution section, operation table, counting instrument. Use PLC to control ,set and adjust the length. Both man-made and auto operations: on the man-made condition, each equipment can be operated by switch; (4)Hydraulic system  Motor power of hydraulic station: 3KW Function: apply power for Cutting Machine (5)Manual receiving table

Motor power of hydraulic station: 3KW Function: apply power for Cutting Machine (5)Manual receiving table  4, Flow Chart Passive feeding--guide feeding--roll forming--cut to length--run out table

4, Flow Chart Passive feeding--guide feeding--roll forming--cut to length--run out table  Workshop

Workshop  Delivery

Delivery  Passing CE, Guaranteed quality. PLC control system, Easy to handle Whole-process technical trace service Direction to production line operation. Design according to your requirements. Contact us if you need more details on Roll forming machine for Door Frame. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Door Frame Making Machines、Door Frame Bending Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Passing CE, Guaranteed quality. PLC control system, Easy to handle Whole-process technical trace service Direction to production line operation. Design according to your requirements. Contact us if you need more details on Roll forming machine for Door Frame. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Door Frame Making Machines、Door Frame Bending Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Door frame machine

Premium Related Products